WALGETT SHIRE COUNCIL

COLLARENEBRI EMERGENCY ARTESIAN BORE WATER

Supply System and associated infrastructure

Project Timeframe

Start Date: June 2020 - Completion date: September 2020

Project Address:

Collarenebri NSW

Client Name:

Walgett Shire Council

Project Value

$1.75mil (including bore drilling)

Key Components

Water supply Infrastructure, Remote & Regional Works, Pump Station Works

0408 635 818

0417 104 586

Project Overview

Collarenebri town water supply is sourced from the Barwon River and stored in a raw water storage reservoir then feed via a gravity pipeline to Council’s Water Treatment Plant (WTP). The existing system is under high stress as the river is running dry with a major drought in place.

Walgett Shire Council intends to commission the Design and Construction of an Artesian Bore and Water-Cooling Tower infrastructure to secure reliable constant water supply to the township of Collarenebri in years of drought.

The project had several major hurdles to overcome to be able to supply bore water security, firstly the bore had to be drilled to a depth of over 1200mrts to find a reliable water source that would be adequate for the town supply. After the bore was constructed the major issue was the temperature of the water which was at 50 degrees once it reached the surface this would have to be cooled to around 27 degrees to be able to be treated at the WTP this meant the construction of a large Cooling Tower to be able to drop the temperature to the required temperature of around 27degrees.The system design is all controlled via PLC control system which is temperature controlled and regulates the flow from the bore through boost pumps to the raw water reservoir insuring the temperature doesn’t exceed 27degrees at any time.

Works Undertaken

Artesian Bore

- Drill a 200mm Stainless Steel cased bore to a depth of 1200mrts to find an adequate supply.

- Bore was constructed by Impax Drilling with a flow rate of 40l/s @ 50degrees Celsius

- Testing and Commissioning of bore system.

Boost Pump System

The 1st Boost pump will be constructed at the Bore Site this pump system will have capabilities to pump the bore to its full capacity of 40l/s and boost the pressure to 150kpa which will be enough pressure to run the cooling tower system and also have the required pressure to run through the proposed cooling system the 2nd pump situated after the cooling tower is to pump to the existing reservoir through the new pipeline. The Pump system will be fitted with a Variable Speed Drive starters to fine tune to the desired pressure, the pumps selected are a 100L- 200 Inline Circulating Boost pumps.

Water Meter & Discharge Pipe work

All pipe work from the bore head through the pump and into the ground will be 150mm Stainless Steel schedule 40 grade and all associated valves and fittings will be Stainless Steel, the Water Meter will be a 150mm Mag Flo meter with a remote display housed in the proposed pump shed, this will be eventually connected to councils’ telemetry system for offsite monitoring.

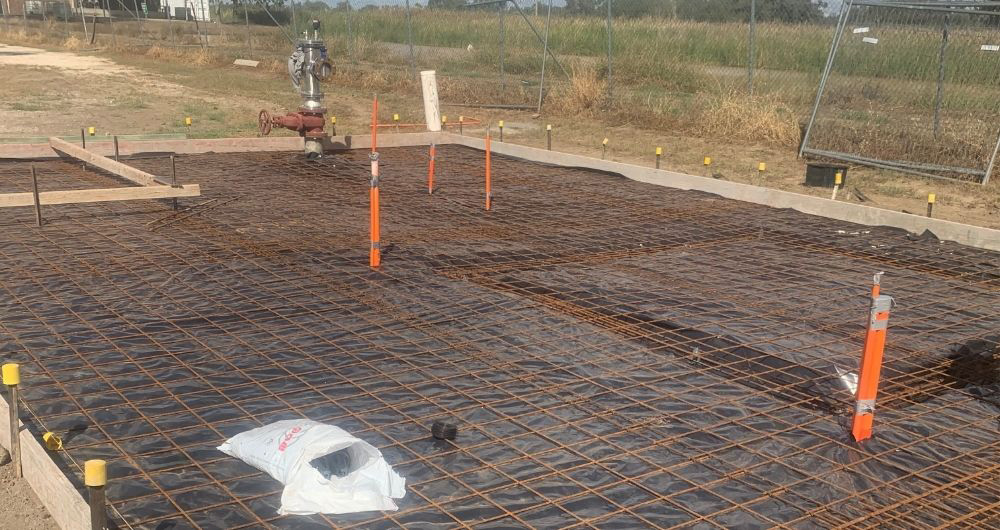

Electrical Pump Shed

A Pump Shed will be constructed at the bore site to house all required all electrical in a dust free and temperature-controlled environment, the pump shed is situated on as 150mm concrete slab and the shed size is 3.0mrts x 6.5mrts fully insulated and fitted with a reverse cycle air conditioning system

Associated Electrics

A three-phase power supply will run from the WTP to the new bore site the cable size selected will have the capacity to run a 11kw & 22kw pumps as well 18.5kw Cooling Fan and also basic power to the pump station for the future loading All Variable Frequency Drive starters will be installed and fitted with shielded motor cables and conduits, emergency stop button and a start/stop/speed control switches included Supply of cable trays within pump shed, internal and external lighting, power outlets (2) small distribution board with safety switches, single phase split air conditioner unit. Electrical installation will consist of Power supply form WTP to Bore site, VFD and filter installation, installation of cable trays, installation of sub board, installation of general light and power, installation of remote water meter display, installation of air con unit, make all connections and test and commission.

Pipeline from Cooling System to Reservoir

The pipeline that will travel from the Cooling Tower pump to the Reservoir and will be PN10 x 225mm Poly pipe which is capable of temperatures up to 60 degrees if required. This pipe work will connect to the pipe work at the base of the reservoir, there will be isolating, and non-return valves fitted at both ends of the pipeline to prevent backflow to the cooling tower.

Highlights, Innovations and Key Risks

- Delivering Water Security to remote isolated township

- Infield modifications to adapt to council requirements.

- No major disruption to town water supply through the project duration.

- Ongoing discussions with council to improve the water supply system

- Excavation and pipe laying in proximity to existing infrastructure.

- No underground service strikes for the duration of the project